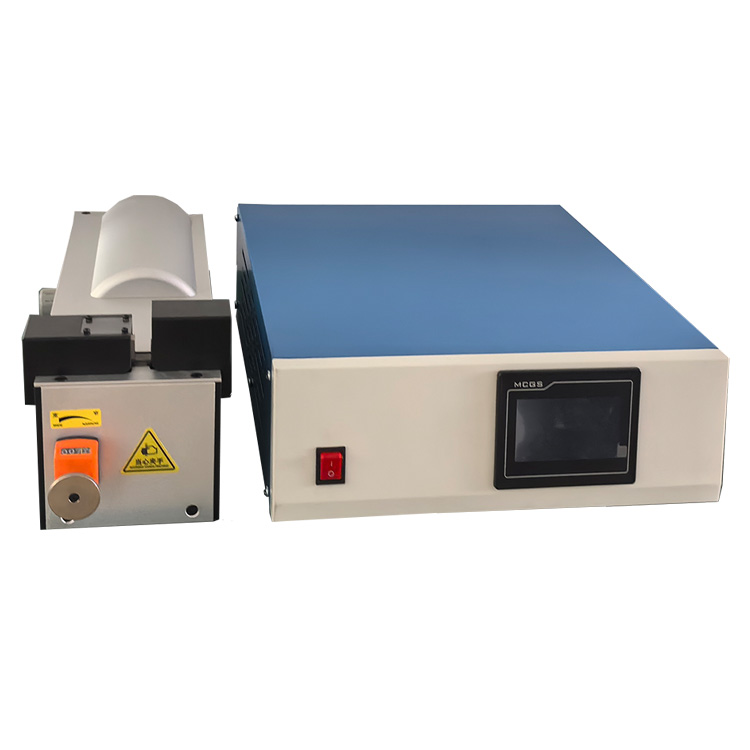

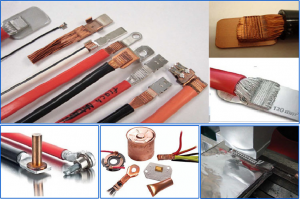

I-Ultrasonic Wire Splicing Machine SA-HJ3000 yindlela ejoliswe kwixesha elizayo yocingo kunye nezicelo ze-terminal. Phakathi kwezinye izinto inkqubo isetyenziselwa ukudibanisa iingcingo ezininzi kunye nomnye kunye nokudibanisa iingcingo ezineetheminali zokumisa okanye i-high-current contacts.Xa kuthelekiswa ne-crimping okanye i-resistance welding, le nkqubo ibonelela ngeenzuzo ezininzi. Ngaphandle kweempawu ezibalaseleyo zombane ezidibeneyo kunye nokusetyenziswa kwamandla aphantsi kakhulu, le ndlela ibonakaliswe ngokukodwa ngokulawulwa kwenkqubo ebanzi kunye nenkqubo yolawulo lwedatha.Umatshini we-welding yisisombululo esitsha se-ultrasonic wire splice solution. Idibanisa iingcingo eziphothiweyo, eziphothiweyo kunye nemagnethi ukwenza intambo yocingo, intambo yocingo okanye intambo yebhetri. Uqhagamshelo oluvelisayo lusetyenziswa kwimizi-mveliso yeemoto, inqwelomoya, ikhompyutha kunye nabathengi bobuxhakaxhaka bombane, kunye nolunye ulawulo lwenkqubo kunye nokusetyenziswa kwezixhobo zokusebenza. Isetyenziswa kakhulu ekuveliseni iintambo zocingo.

1.Uhlengahlengiso oluzenzekelayo lobubanzi be-splice ukusuka kwi-0.5-20mm2 (kuxhomekeke kwinqanaba lamandla)

2.Ulawulo lwe-Microcomputer, i-electronic tuning frequency.

I-3.Amandla ahlengahlengiswayo, asebenze ngokulula, kwaye aqhube ngokuzinzileyo kwaye anokwethenjelwa.

Umboniso we-4.LED ugcina umatshini obonakalayo ekusebenzeni kunye nokulawula.

5.Amacandelo angeniswayo, ukusebenza kakuhle kwimveliso yamandla.

I-6.Ukukhuselwa ngokugqithisileyo kunye nesiqalo esithambileyo kunokugcina umatshini ukhuselekile.

7.Ufakelo olulula kunye nokusebenza.

8.Not kuphela isinyithi efanayo, kodwa dissimilar zonke unako welding kunye. Iyakwazi ukuwelda isilayi sentsimbi okanye iyeke kwintsimbi eshinyeneyo. Idla ngokusetyenziselwa itransister okanye iIC's lead welding.